Turnkey Solutions for Food Service and Laundry Equipment

EKE’s Scope covers Supply, Installation, testing & commissioning of Food Service Equipment as detailed on Contract Specification and Approved Drawings.

Setting the Bar High: Our Industrial Kitchen Triumphs

Welcome to Emirates Kitchen Equipment, where we excel in delivering top-notch project management services right from the project’s inception. Our commitment lies in providing clients with well-structured and budget-friendly solutions tailored to meet the unique demands of each project.

- Co-ordinate with electro / Mechanical contractor to ensure services are correctly positioned

- Co-ordinate with HVAC contractor on exhaust hood final connection

- Co-ordinate with fire & Safety contractor to interface the fire suppression system on the hood.

- Co-ordinate with civil contractor if any opening in walls are required to run cold room piping

- Interfacing with Electro Mechanical Services

- Ensure electrical services are laid down as per approved MEP drawing

- Ensure fine suppression system in hoods are connected to fire alarm control panel

- Ensure gas supply line is provided with corrected gas pressure regulation & valves

- Ensure water & drains are laid down as per approved MEP drawing

At Emirates Kitchen Equipment, we are dedicated to delivering excellence in project management, assisting you in creating a functional and exceptional kitchen space that meets and exceeds your expectations. Let us help you turn your culinary vision into a remarkable reality.

Our designing team comes up with brilliant, innovative and most modern concepts on Auto Cad which transforms in to a fully equipped, well appointed, practical kitchen.

As a first stage in the entire process, the bill of material shall be verified and approved by specialist contractor – EKE’s Certified Engineer to make sure that all the correct equipment’s are selected and included to make the system completely operational as per the job specification requirements. Any mistakes or incompatibilities shall be eliminated from the bill of material at this stage. It must also be confirmed by the concerned engineer that all the equipment’s are approved by concerned authorities as per the requirements of job specifications and authority having jurisdiction. Any component incompatibility or conflict with the job specification shall be brought out and reported to the concerned. Any changes in the bill of material to satisfy above requirements shall be informed to the concerned contractor.

Before the required materials are shipped to the concerned project/site, a manufacturer’s factory test is essential to verify that all the material to be shipped is in proper order. Visual, Functional and Operational tests shall be carried out.

A complete list of material being shipped shall be verified to match with the requirements specified in the material order. The equipment goes through a rigorous Quality check and is manufactured in various ISO 9000 certified factories. All the components shipped from the factory are therefore in proper order and accompany all the necessary installation guidelines & operation manuals. All the equipment shall be treated in accordance with the guidelines issued by Manufacturer. Following points shall be strictly followed.

- After receipt of the material at site, proper handling care shall be taken while unloading the same.

- All the shipments from Manufacturer come with a packing list. All equipment is shipped in a protective cover. This cover should not be removed until the device is ready for installation. These devices shall be handled and stored with the protective cover on.

- Each packing box contains installation guidelines and installation accessories. It is necessary to use these installation accessories to install the device and the same should be done exactly as mentioned in the installation guidelines.

- Storage of the material shall be in an enclosed space free from water leakage and excessive dust. All the electronic component has shelve life, which deteriorates if the environmental conditions are adverse. In a few cases, the device may fail to function due to exposure to environmental condition beyond the specified capacity. In all cases, the environmental storage limits as specified shall be considered. Almost all components accept storage temperature range of 0 to 49 degree C and humidity of 0 to 93% Rh non-condensing. Storage conditions must be within these limits.

- Removal or replacement of any part of the equipment in the field except by the certified engineer and with the equivalent approved part is to be avoided. EKE does not recommend any field modification of equipment.

- Instruction to be followed as per installation, operation & maintenance manuals

Reimagine Culinary Spaces with Our Expertise

Installation is as important as the quality of the material. Wrongly installed equipment often generates problems over a period of time after the start of operations. All the equipment’s are provided with installation guidelines in the packing boxes. These sheets contain the most recent and accurate information on device installations. It is must to follow the installation practice as described in the relevant installation manuals. Cabling, plumbing and service connectivity are the most important part in any field installations.

Any changes in the installation from that shown on the drawings shall be marked on site and corrected drawings shall be reissued. Any major changes during installation may call for a new drawing to accommodate the same.

Two activities go in parallel at this stage. The various equipment’s installed are verified as per the final drawings to check the correctness and to remove all the faults so that it is all ready for commissioning. The programming of the various equipment’s is preplanned and must be done by specialist contractor – EKE’s Certified Engineer to incorporate all the functionality’s required as per the job specifications. The programming sequence shall be properly documented as per the relevant specification of the project.

The commissioning procedure shall be pre-planned and documented before starting the actual commissioning. The addresses of modules shall follow the approved shop drawing. This chart shall be used as a reference and fill up sheet during commissioning. The appliances shall be checked against as programmed and desired. All the responses shall match with those required.

The final version of the commissioning report shall be signed by the commissioning engineer and the inspecting engineer. This report shall form a part of the document to be transferred to the end user.

In view of the multiple manufacturers from diverse countries involved for the equipment under our scope of works, the manufacturers can not provide direct individual technical support.

We, however, confirm that as the contractor / supplier for the equipment proposed, we will provide technical support for the items supplied & installed under our scope of works for the warranty period.

"Unleash the Power of Innovation in Your Professional Kitchen"

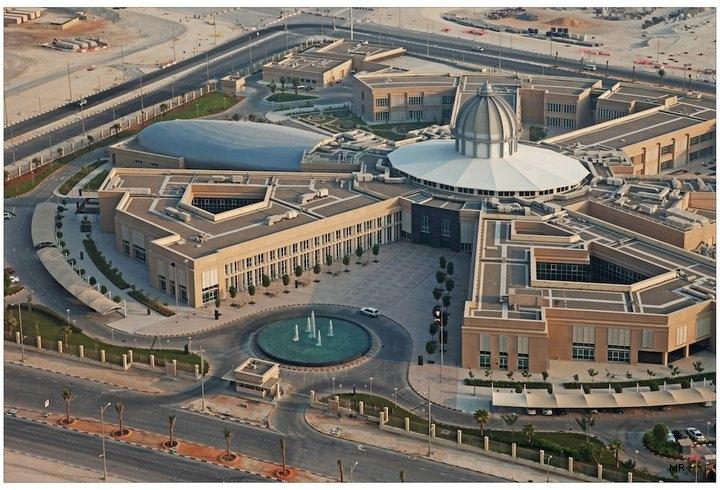

Our Projects

A Glimpse into the Future of Industrial Kitchen Engineering